Call: 08045475466

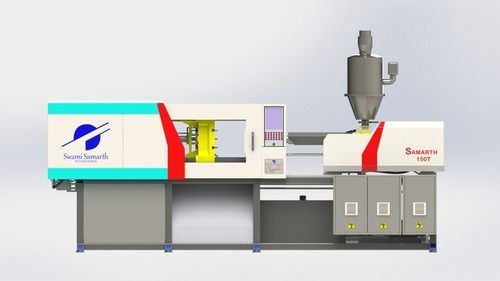

Horizontal Type Injection Moulding Machine

1000000 INR/Set

Product Details:

- Product Type Industrial ,Electrical ,House Hold Products

- Material Stainless Steel Alloy

- Type Preform Injection, Plastic Injection Molding Machine

- Style Horizontal

- Capacity 60-800 Ton/day

- Automatic Yes

- Feature Lower Energy Consumption, ECO Friendly, High Performance, Low Noise, High Efficiency, High Speed Response, Smooth Running

- Click to View more

X

Horizontal Type Injection Moulding Machine Price And Quantity

- 1000000 INR/Set

- 1 , , Set

- 1000000.00 - 1500000.00 INR/Set

Horizontal Type Injection Moulding Machine Product Specifications

- Stainless Steel Alloy

- Lower Energy Consumption, ECO Friendly, High Performance, Low Noise, High Efficiency, High Speed Response, Smooth Running

- Industrial ,Electrical ,House Hold Products

- 1 Year

- Preform Injection, Plastic Injection Molding Machine

- 60-800 Ton/day

- Yes

- Horizontal

Horizontal Type Injection Moulding Machine Trade Information

- Nhavasehva

- Letter of Credit (L/C), Cash in Advance (CID), Cheque

- 2 , , Set Per Month

- 1 Week

- Australia, Middle East, Africa

- Tripura, Manipur, Dadra and Nagar Haveli, Himachal Pradesh, Pondicherry, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Lakshadweep, Delhi, Gujarat, , South India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Haryana, Jammu and Kashmir, Jharkhand, Kerala, Madhya Pradesh, Mizoram, Meghalaya, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, West Bengal, Nagaland, Maharashtra, Uttar Pradesh, Karnataka, North India, Central India, Odisha, Chhattisgarh, All India

Product Description

Features :

- Rigid design

- High efficiency

- Require less maintenance

POLO Series Advantages :

- With super big tie bar space and clamping stroke

- With faster heating, and more precise temperature control

- With super big eject stroke

- With big diagonal type clamping unit design, easy mould open and the clamping unit running fast

- Flexible front platen design, with little large-area deformation.

- Two paralyzed Piller guider design injunction is more stable & precise.

- Injection Moulding Machine

- Separate Panel

- Sturdy and Optimized Five Point Toggle System

- Air Recovery System

- Motion Analysis

- Discharge conveyor

- Special Strengthen Thread Hole With T-Slot

B & R Automation

- Cut down your costs significantly

- Best price/performance ratio

- B & R : World leader of plastic machine automation

- HMI, PLC, IOs and Servo from one source

- High speed scan time < 2ms

- Power Panel PP65, keys, 10.4" VGA TFT

- Injection Moulding Machine

Servo System Combines Servo Motor

Benefits:

- Energy saving: Compared with traditional constant/ variable displacement pump system, the servo pump system combines servo motor fast step-less regulation pump self pressure adjustment, bringing tremendous energy saving which reach up to 80%.

- Position repetition accuracy.

- Pressure control accuracy.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese